Powered by Advanced AI

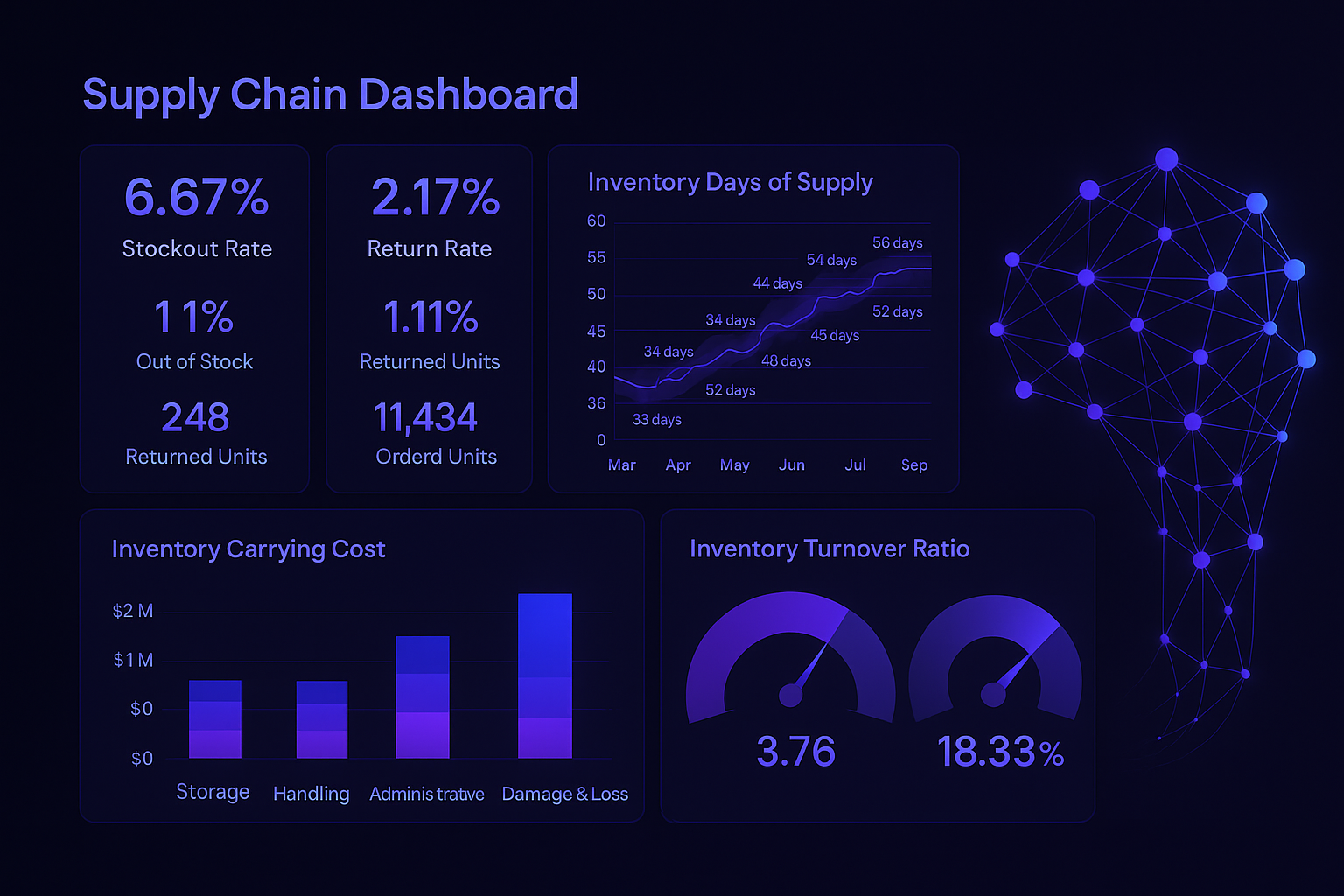

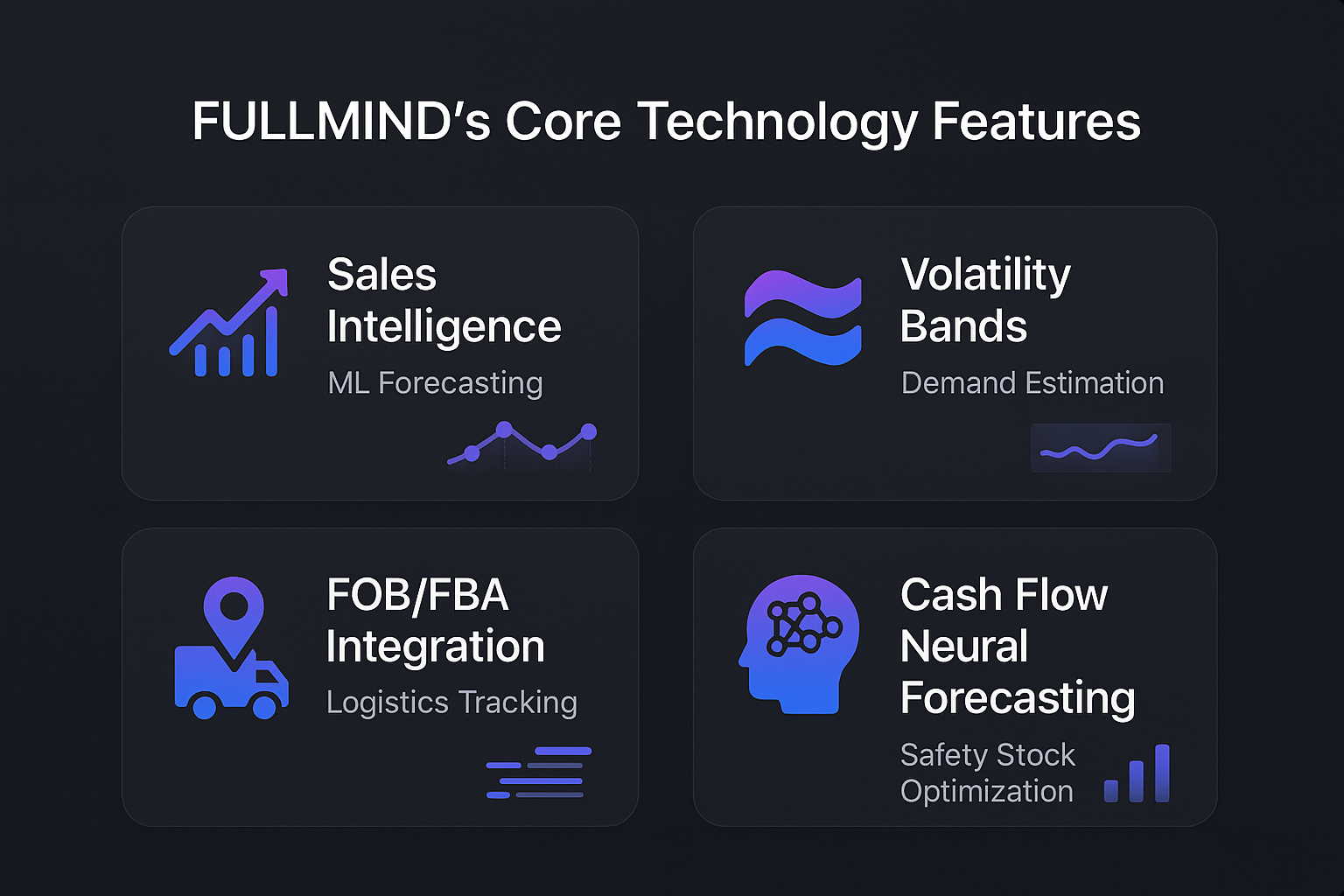

FULLMIND combines cutting-edge machine learning algorithms with deep supply chain expertise to deliver a comprehensive solution for Amazon sellers.

Our core technology features work together as an integrated system, providing you with unprecedented visibility, control, and optimization capabilities across your entire supply chain.